Knife sharpening equipment

I'm a novice at best when it comes to cooking, but I'm open to learning how to sharpen my own knives. However, I'm a quite overwhelmed with where to start and how to get things going. I have a few questions:

- What should I look for when purchasing a whetstone?

- Should I buy a lower-end set of knives to practice on first?

- Why would one opt to use an electric sharpener over a whetstone?

Best Answer

A stone is the hardest way to sharpen a knife. If you don't get the angle exactly right, you'll just be messing up your knife, not sharpening it. If you do want to go that way, yes, you'd definitely want to practice on something cheaper, because it's likely you will mess it up. This is why a lot of people just take their expensive knives to a professional to get sharpened. I've seen good knives sharpened into oblivion before - totally reshaped blades, and still not even really sharp.

Most electric sharpeners are designed to avoid all this - the good ones have a fixed angle sharpening surface, and something to hold the knife in the right orientation, so you can't mess it up. The one caveat is that Western style knives have 20° edges, while Japanese style ones have 15° edges, so for example in the US, the sharpeners you buy won't be good for Japanese style knives.

Additionally, you don't actually need to sharpen them very often at all. Periodically honing your knife will keep it pretty darn sharp, especially if it's a decent knife and you take good care of it otherwise. Give that a try, and you may not feel you need to sharpen it for a long while. At that point, since you won't be sharpening it all that many times in your life, it may not be worth learning to sharpen the hard way - a professional or an electric sharpener will be a lot easier.

But if you do want to get a stone and teach yourself, the thing to do is probably to start with a finer-grained one, so you can't destroy the knife as easily. You can practice getting the angle exactly right, doing finer sharpening. Hopefully that's all you'll need, but if you ever need to do more, once you've got some practice, you can move on to a coarser stone for really reshaping the blade. (Or... you can apparently save money and use sandpaper.)

Pictures about "Knife sharpening equipment"

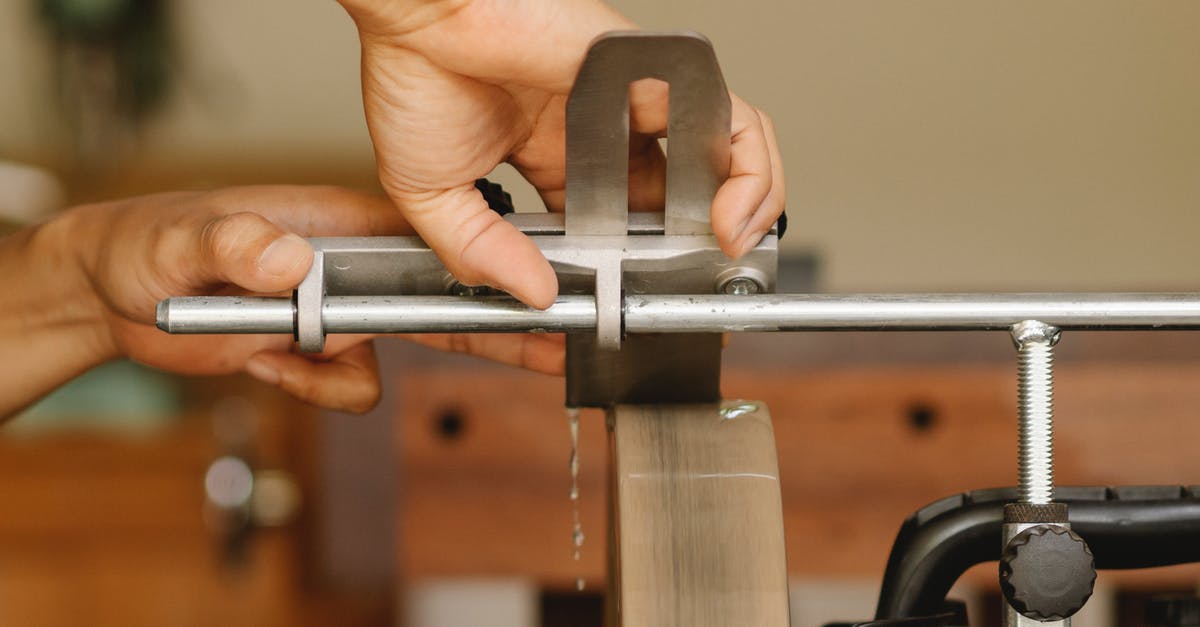

What do professionals use to sharpen knives?

Most of the knives are sharpened with my two main methods; the WickedEdge system or the Tormek, but there are exceptions even to these two methods. For most knives, I use the Tormek slow wet grinding sharpening system. The wheel on this system only rotates at 90 rpm. I use two Tormek machines in my process.What piece of equipment is used to sharpen a knife?

A waterstone (or whetstone) is essentially a rectangular block of stone used to sharpen and hone the edge of a knife \u2013 or any other sharp steel tool, really.What is the best way to sharpen my knives?

When sharpening iron during forging, blacksmiths use sharpening stones such as waterstones, oilstones, and diamond sharpening stones. To rejuvenate and re-sharpen iron blades, blacksmiths may either use these stones or tools called honing rods.Razor Edge Systems | Knife Sharpening System

More answers regarding knife sharpening equipment

Answer 2

Bob Kramer has an excellent series of youtube videos about honing and sharpening your knives:

What is Sharp? http://www.youtube.com/watch?v=xRPrswhMdAc

Honing: http://www.youtube.com/watch?v=MUdrRE7W0b4

Stoning: http://www.youtube.com/watch?v=lUbkPdkUDuo

Keys are using the correct angle (he uses a matchbook to set the angle), using enough pressure (5 lbs, use a scale to get a feel for it), and testing sharpness on a piece of paper.

I recommend getting a thrift shop knife to practice on. I picked up a combination coarse/fine sharpening stone at my local hardware store. I think it's 400/1000 grit. The coarse side shapes the blade. The fine side smoothes out the scratches from the coarse side. Honing does the final sharpening. If you only get a fine stone you may not be able to reshape the blade in a reasonable amount of time.

Answer 3

1) This is advice on going the waterstone route. Let someone familiar with oilstones fill in on oilstones.

In general, look for a waterstone of a brand that is well known in knife owner's circles. The King/Sun Tiger 1k/6k is a good example.

You want (all grits are japanese, not FEPA grits!) :

- a 800-3000 grit for main sharpening of blades in good condition.

- a 200-400 grit stone for repairs, thinning, angle changes, sharpening very blunt knives, flattening other stones.

- one or more 3000-10000 grit stones (or comparable natural stones like the belgian blue or coticule) as finishers. Do not get ONLY a >6000 grit finisher unless you also have either a coarser finisher as an intermediate step, or a main sharpening stone that is on the finer (2000-3000) side.

Special qualities a waterstone can have (the King/ST I mentioned has none of these, but that is why it is economical):

- "splash and go" behaviour (does not need soaking as most other waterstones do)

- high dish resistance (less need to flatten - but when the need arises, the flattening will be harder. Also, very dish resistant stones can show some clogging behaviour)

- Ability to do a mirror polish(for finishing stones) - eg the naniwa superstone series in the finer grits are great at that.

- Ability to do a contrast finish on the secondary bevel of a laminated blade (actually, the king can do that, sort of)

- very high speed (in relation to the grit) - diamond based stones are actually best at that, but inexpensive diamond stones can bring other unpleasant surprises into the equation.

2) Yes - but use knives where the steel and temper used is known (eg, "420J2 at 54HRC" or "VG10 core at 59HRC"), so you can put whatever phenomena seem to affect one knife but not the other in context.

3) No manual skill beyond following the instructions skillfully will be needed. Waterstone and oilstone sharpening are more of a craft than a utilitarian skill. Also, manual sharpening (especially when it is about more than just refreshing an edge) is messy work: Waterstones tend to leave stone slurry and swarf all over the place, while oilstones tend to be used with potentially non food grade oils that you need to keep from contaminating food and food utensils.

However, electric sharpeners are regarded as widely differing between each other in the edge quality and knife longevity they can give. Almost all of them are unable to do thinning when needed, or use a deliberate custom choice of edge angle, or do compound bevels, or do asymmetrical bevels. Note that machines with open rotating whetstones (eg a Tormek machine) are more like whetstones than electric sharpeners for this comparison. Note that generic, machine shop type bench or belt grinders are generally considered a bad choice as a sharpening tool for anyone except a knifemaker/experienced sharpener who knows what he is doing - they can damage both the knife and the user beyond easy repair quickly.

Sources: Stack Exchange - This article follows the attribution requirements of Stack Exchange and is licensed under CC BY-SA 3.0.

Images: Ono Kosuki, Ono Kosuki, Ono Kosuki, Ono Kosuki